Formulation R&D

Formulation Research & Development

What is formulation research?

The process aims to develop formulas to effectively deliver product benefits or enhance textures

for a more satisfying product experience. LG H&H’s R&D Center makes relentless effort to

develop new forms of products suitable for different product categories.

Main Areas of Research

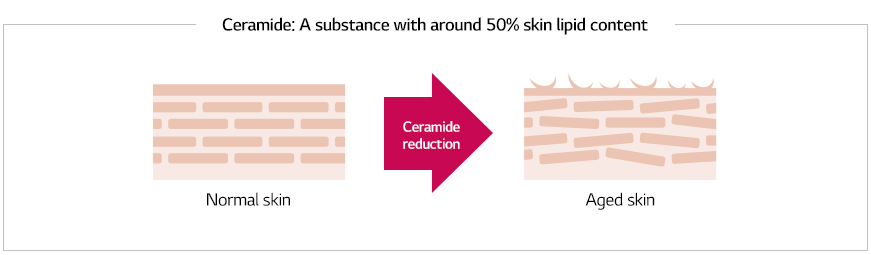

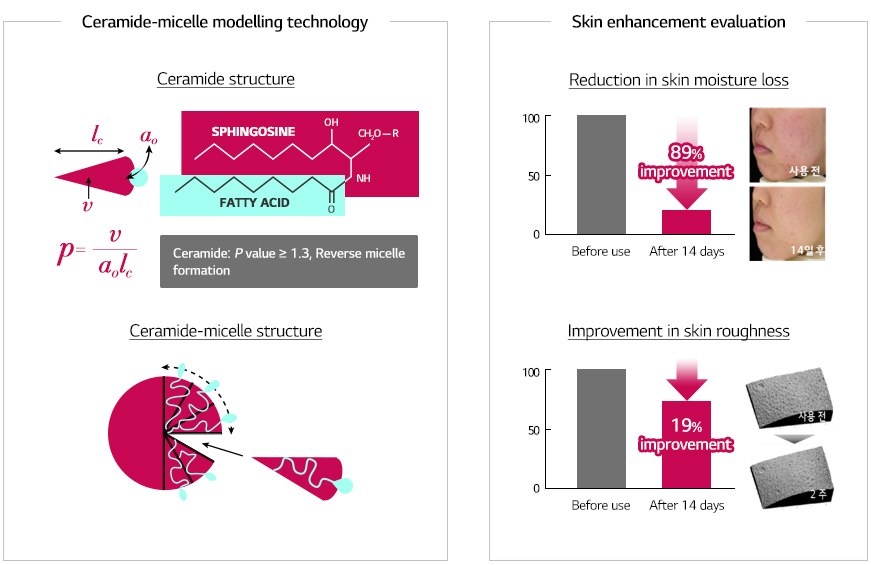

Technology to stabilize poorly soluble ceramides for skin barrier reinforcement

While ceramides are known to be highly effective in repairing damaged dry skin, they are poorly soluble and prone to precipitation, a feature that makes it complicated to formulate them. As a result, our old ceramide particles were too large to easily penetrate the skin, and it was difficult to develop lightweight ceramide formulas for a toner or essence.

Yet, we have developed a technology to increase the ceramide content in products, inspired by the idea that surfactants in a water solution aggregate to form micelles. To create stable forms of particles applicable to transparent formulas, we succeeded in making surfactants and ceramides form micelles together to achieve an average particle size of 40nm.

Leveraging this technology, we have created lightweight yet hydrating formulas that were not seen in previous ceramide products. Also, boasting great skin penetration abilities, the new ceramide formulas have been applied to our flagship essence products.

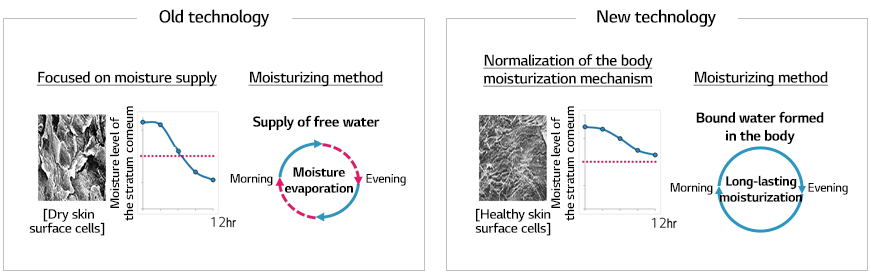

Technology to improve the skin’s moisture retention

A lack of moisture weakens skin cells, and in turn accelerates skin aging. So, locking in moisture is highly important when it comes to maintaining healthy skin. Yet, temporary moisturization often fails to improve the fundamental moisturizing condition of dry skin.

At LG H&H, we have developed technology to help the skin retain moisture on its own, based on the concept that the lamellar structure* of the stratum corneum retains bound water for a long time. The idea is that a formula loaded with lipid complexes that are similar to the skin’s lamellar structure strengthens the skin’s ability to bond with water. Indeed, clinical tests have shown that this technology effectively increases the skin’s moisture level.

*Lamellar: A thin layer of fat in the skin

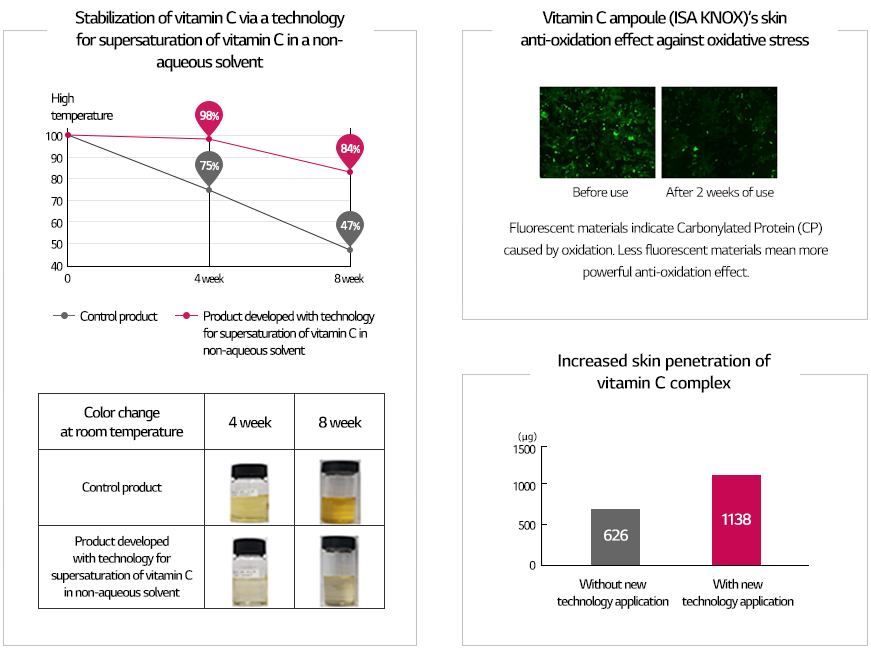

Formulation technologies to stabilize vitamin C, a substance that is vulnerable to light, heat & oxygen and is not easily dissolved.

Providing various skin benefits, including outstanding anti-oxidation capabilities, vitamin C has long been touted as a hero ingredient in the beauty industry. Yet, vitamin C is prone to oxidative degradation when exposed to heat or humidity, a feature that makes it challenging to develop vitamin C-enriched skincare formulas.

At LG H&H, we have been developing various formulation technologies to stabilize vitamin C and deliver potency to the skin. As the skin and vitamin C are both negatively charged, they tend to repel each other, a factor that decreases vitamin C’s skin penetration. As a result, we have neutralized the negative charge of vitamin C in order to enhance its skin absorption.

Given that vitamin C is prone to oxidation when exposed to humidity and heat, we have developed a formula that remains stable even at low temperatures, and operate our own cold chain system to ensure that vitamin C becomes dissolved in a non-aqueous solvent as much as possible.

Going forward, we will continue to develop formulation technologies that ensure the effective delivery of active ingredients, including vitamin C.

Foundation formulation technologies for various applicators

The goal of base makeup is to create a flawless complexion. While it takes a lot of effort to create a natural makeup look, regular liquid foundation products require tools for application, a factor that makes them difficult to use conveniently and on the go.

With this in mind, LG H&H has created new applicators and matching foundation formulas.

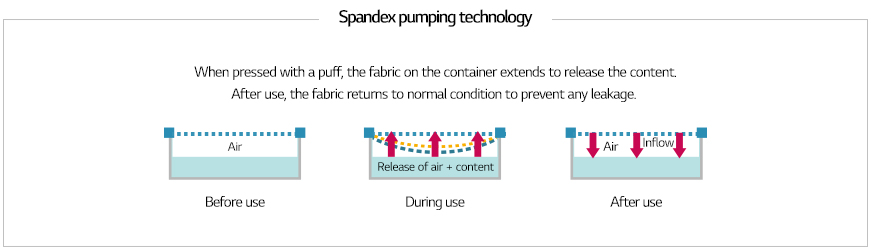

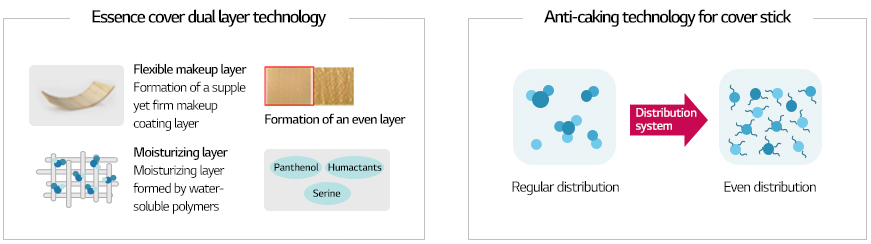

We have unveiled and marketed portable and easy-to-use foundation product lines with convenient applicators, including a cushion foundation with a dual spandex net to minimize product leakage, a pumping foundation that offers the benefits of a cushion foundation thanks to the essence cover dual layer technology, and a cover stick designed to minimize cakeyness.

Going forward, LG H&H will continue to develop trend-leading applicators, and secure technologies to formulate foundation formulas tailored to different applicators in order to provide new product experiences to our customers.

Dual coating lip color formulation technology for long-lasting color

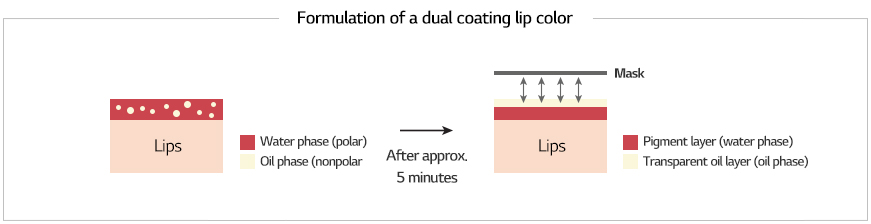

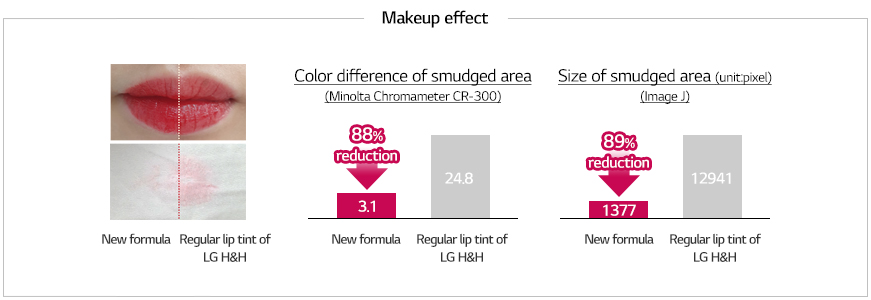

Given that mask-wearing has become the norm amid a prolonged COVID-19 endemic, demand for transfer-resistant lip makeup products has expanded. While water tint formulas are known to be more transfer-resistant compared to other types of formulas, they often cause dry lips, requiring the layering of a moisturizing lip oil.

In response to this issue, LG H&H has developed a dual coating formula that colors the lips like a lip tint while forming a separate transparent oil layer. Based on the underlying principle that oil and water do not mix, the new formula boasts water-soluble pigments that adhere to the lips for long-lasting coloring, with a separate oil coating layer protecting the lips from dehydration.

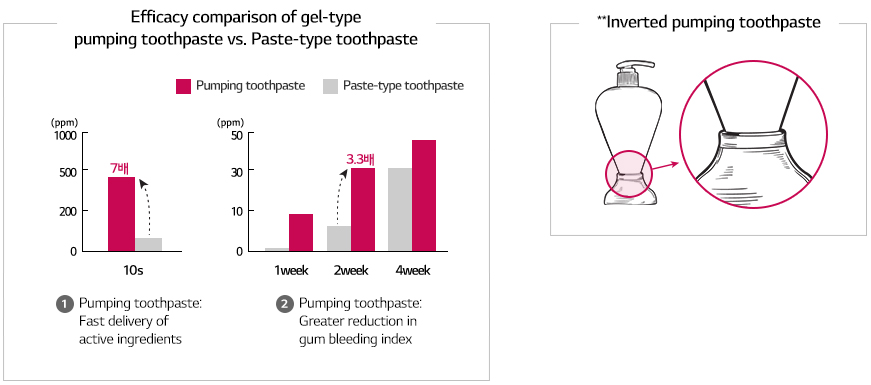

Pumping toothpaste: A toothpaste for more effective delivery of active ingredients and convenient use

It is generally recommended to brush the teeth for three minutes to ensure that the toothpaste’s active ingredients are effectively delivered to the oral cavity. Yet, people often fail to fully follow this faithfully.

At LG H&H, we have developed a toothpaste formula to effectively deliver active ingredients even with brushing the teeth in a short time. We have also adjusted the toothpaste’s rheological properties to create a dispenser-type pumping toothpaste that is more convenient to use than a tube-type toothpaste.

According to the results of our clinical trials, a gel-type pumping toothpaste with improved flowability is proven to deliver active ingredients fast to the oral cavity, and thus show greater efficacy versus plain paste-type toothpastes. Furthermore, we have developed an inverted** pumping container to easily squeeze out every last drop of toothpaste.

*Gum bleeding index improvement

1Delivery of active ingredients: LG-Gel-Type-Paste, a Novel Toothpaste Formulation with Fast Drug Release,

Korean Pharmaceutical Association’s Fall Academic Conference (2013)

2Gum bleeding index: Magnolia Cortex, Centella Asiatica and Zea Mays L. Contained Dentifrice according

to the Phase Influence to the Oral Environment, Int J Clin Prev Dent 2017;13(2):53-58

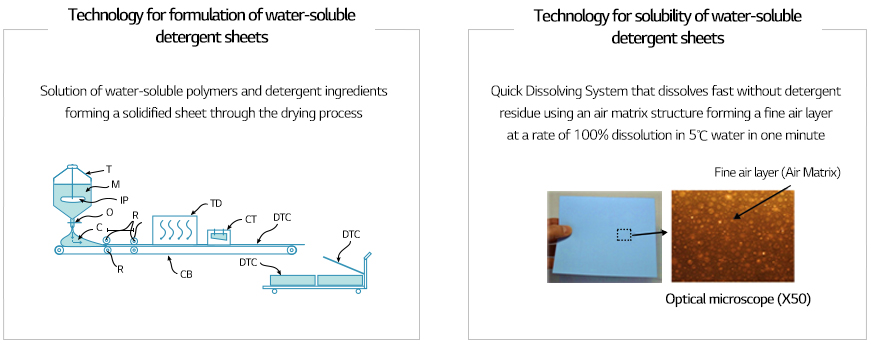

Technology for fabric care sheet formulation

Clean laundry requires not only a good washing machine, but also a high-quality detergent. While powder detergents were widely used in the past, they increasingly gave way to liquid detergents due to powder dust, residue on laundry, and difficult storage. Yet, liquid detergents are not always convenient to use as they are heavy and often leak while measured with the cap.

For more convenient detergent use, we have created a sheet-type detergent by mixing water-soluble polymers and detergent ingredients with water, spreading the solution in a thin layer, and drying it. Detergent sheets are lightweight, easy to store, and do not leave a residue as a fine air layer helps the sheet dissolve fast when soaked in water.

LG H&H will continue to pursue research activities, and deliver innovative, cutting-edge products for a more convenient customer experience.

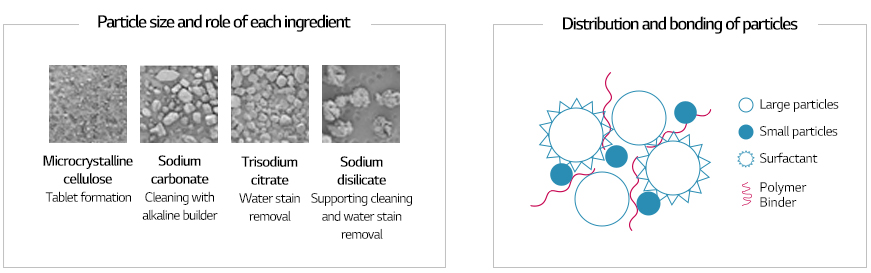

Technology for dishwasher tablet formulation

A dishwasher, which is a modern convenience that reduces a major household chore, has become essential in households today. With the rising use of dishwashers, there has been an increasing demand for dishwashing detergents with strong cleansing power, and water stain removal effect.

To create an all-in-one tablet detergent with both cleaning and rinsing properties, LG H&H has adopted a technology to reinforce the bonding of detergent particles and chelating agents to prevent water stains. Furthermore, enzyme ingredients have been added to effectively remove residue of Korean foods including clinging rice grains, red seasonings, and sticky meat grease. Lastly, we have reduced the size of the tablet to help customers adjust the detergent amount according to the number of the dishes.

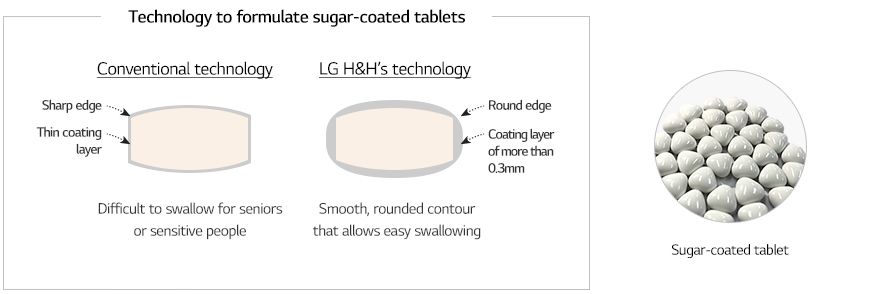

Technology to formulate sugar-coated tablets for effective delivery of functional ingredients

Health functional foods are often produced in the form of tablets, capsules, or liquids. When formulated as tablets, functional ingredients may give an abnormal odor or a bitter taste. Furthermore, they often degenerate during storage as they are vulnerable to light and humidity.

LG H&H possesses an exclusive technology to formulate sugar-coated tablets. A sugar-coated tablet has a smooth, rounded contour, and is coated with sugar and calcium to give a sweet taste for easy swallowing. Moreover, it effectively protects the active ingredients inside to retain its potency. At LG H&H, we have set an optimal ratio of sugar and coating conditions for each production step to standardize technology and stabilize product quality.

Health functional foods diversify in taste and formulas to provide customers with a delightful sensory experience. LG H&H will further strive to develop products with superior efficacy and safe ingredients.

Technology to stabilize highly concentrated protein/calcium drinks for easy consumption and digestion

With keen customer interest on health care, demand for health supplements infused with protein and calcium, which are essential to form healthy muscles and bones, has been rapidly expanding. As for protein supplements, while power formulas were favored in the past, ready-to-drink’s have gained popularity as of late. At the same time, a highly concentrated protein drink often causes coagulations through the interaction between protein and calcium, resulting in poor digestion and absorption ready-to-drink shakes ->ready-to-drink’s

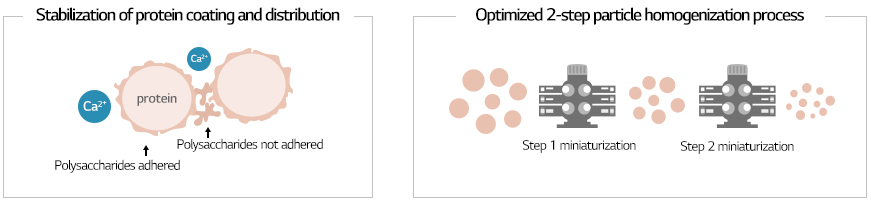

To ensure easy consumption of highly concentrated protein/calcium formulas, LG H&H has developed an exclusive technology to stabilize protein breakdown using polysaccharides that prevent proteins from becoming lumpy, and a two-step particle homogenization process optimized to maintain consistent particle sizes.